Cleanliness coordination in data center construction projects

We ensure your data center project meets ISO 14644-1:2015 class 8 cleanroom specifications throughout the steps from design to handoveby applying over a decade of expertise in Cleanliness Class P1 requirements in construction and maintenance.

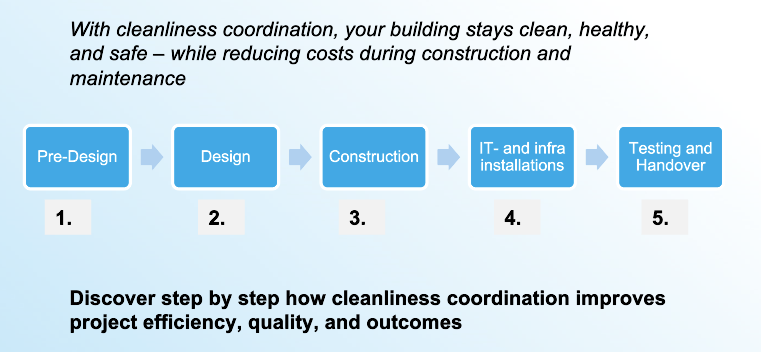

Clean data center – Process in general

- Pre-design and design phase

- Reviewing design guidelines with designers

- Tracking and updating the design task checklist – clean data center tool

- Review of plans

- Preparing a site cleanliness management document

- Legal requirements

- Project requirements at different stages of work

- Construction phase at a clean data center site

- Review and approval of contractor´s cleanliness management plan

- Cleanliness management training

- Regular site visits and inspections

- Model inspections in different tasks like HVAC installation

- IT and Infra installations

- Ensuring that the requirements presented during the design phase are implemented and documented

- Monitoring the work schedule and timetable

- Verification of HVAC installation conditions

- Functional testing

- Verification of specified cleanliness level

- Verification of HVAC system cleanliness

- Testing and handover at clean data center

- Ensuring that the requirements defined during the design phase are implemented and documented

- Monitoring the work schedule and schedule

- Supervising and documenting activities during user installations

- Verifying that the required cleanliness level has been achieved

Benefits of our cleanliness concept

Benefits of Our Cleanliness Management Concept for Data Centers

Our cleanliness management concept is designed to ensure that your data center project meets ISO 14644-1:2015 Class 8 cleanroom air quality standards—through every phase from design to handover.

1. Design Support & Responsibility Definition

We help your design team understand the critical role of cleanliness in achieving cleanroom-grade air quality. Our concept also clearly defines cleanliness-related responsibilities and requirements for the design phase, ensuring that cleanliness goals are integrated from the start.

2. Informed Material Choices

We assist in selecting surface materials that support clean indoor air quality. This helps prevent dust- and dirt-related risks throughout the building’s life cycle, minimizing delays and avoiding unexpected costs.

3. Site Cleanliness Management Documentation

Our concept includes detailed cleanliness requirements for each project phase. These are compiled into a Site Cleanliness Management Document, which is included in contractor procurement materials. This ensures that contractors are held accountable for cleanliness from the outset, with responsibilities that are clear and traceable.

4. Continuous On-Site Inspections

Our experts conduct regular inspections throughout the project to document cleanliness and ensure proactive contamination control. This supports high-quality installations and reduces the risk of contamination-related issues.

5. Safer Worksite & Regulatory Compliance

By implementing structured cleanliness management, we improve occupational safety and ensure compliance with national laws and industry-specific standards. This helps speed up project completion and enables earlier readiness for furnishing and IT installations.

6. Clean HVAC & Equipment Protection

We ensure that HVAC systems are only installed once the required cleanliness levels have been verified. This reduces the need for frequent duct cleaning and helps prevent contamination that could lead to equipment failure. Long-term, this protects sensitive IT infrastructure and contributes to system reliability.

7. On-Schedule Commissioning

With effective cleanliness control in place, testing and commissioning can begin on time—without delays due to environmental contamination. Even during end-user installations, cleanliness can be monitored to ensure consistent quality through final handover.

Ask more of our concept for clean data center building of our staff or our clean data center specialist Juha Takkunen.